Even without EBV, Mainteam goes unconventional ways

The company has been in our focus before. In DD 9 and 14/87, its helmsman and managing director Jürgen Ramminger reported on the pilot introduction of the Reprolog system, an EDP system with online production data acquisition and scheduling. Today, one and a half years later, the workflow at Mainteam has long since become so efficient thanks to this system that the organisation of the company with its centrally controlled AV can be considered exemplary. The DD editorial team has now been informed that Mainteam, Aschaffenburg, has developed a method of controlling every stage of the process via proofs and also selling the end product via proofs; the free press proof capacities can now be used primarily for demanding special jobs.

Exceptional business organisation with significant consequences

Prior to our visit, our editorial team corresponded with Jürgen Ramminger and learned some remarkable things about his thoughts on the use of proofs for intermediate and final inspections. "We produce a proof of 90 % of all raw scans. The cost of this is justified by the security it gives us in terms of customer requirements, including the ability to assess the proof with the customer, decide on litho corrections and mark them precisely. With more intermediate proofs in the production process, we keep our production costs and deadlines under control, because the earlier an error is discovered, the more favourable it is in regard to both factors. It is for all these reasons that we are so committed to the proof! The press proof is known to be influenced by too many parameters and can never be accurately repeated; with our proofs it is much more successful. Often, due to deadlines, mistakes are made in the proof; then the last colour corrections are only sent to the printer as scale notes. In such cases, the proof shows its strength: from the corrected litho, it can be repeated at short notice and thus significantly improve the reliability."

Logically, this consequent turn to a still controversial technology requires a process that guarantees consistency and colour fidelity. Mainteam has apparently found it in Fuji's Color Art, because they have been working with it for a year now and see all the wishes they had for the device and material fulfilled. "To this day, we have not noticed any fluctuations in colouring or sensitivity," Ramminger wrote us. And he knows, because he had been trying to realise his ideas in this respect for several years. A toner process and another well-known film system were left behind.

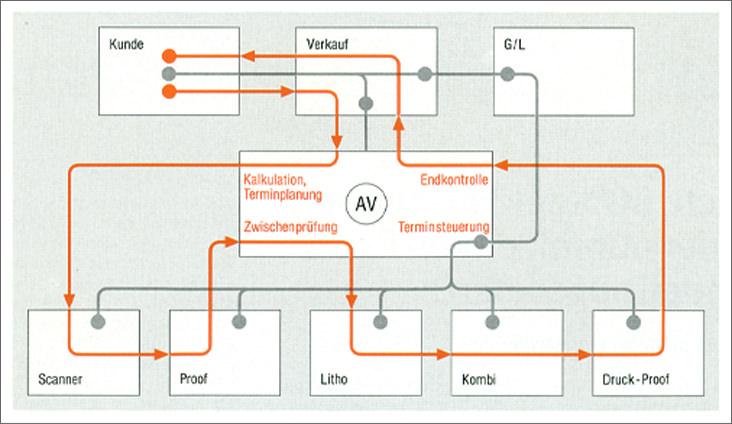

article on "Practical office communication in modern reprographics" and from the the prologik team of BERNSTEIN and CICHOCKI had developed software that made RAMMINGER's idea of controlling the operation via a strong AV highly effective (see also figure 1). And: it really works with the proofs, as already mentioned, they were visibly excellent reference points for the lithos and impeccable legitimations for the final films (see figures 2+3). All of which probably resulted in the fact that there was no repro hectic in this house, that every member of staff could devote himself to his work in a concentrated and relaxed manner. In addition to this and to the fact that he has consciously and without financial constraint renounced EBV until today, we were able to learn the following from Jürgen Ramminger in conversation:

DD: Mr. Ramminger, we were allowed to take a look at your company and were able to see for ourselves that you have created something like a perfect repro organisation with extraordinary methods, such as online production data acquisition and intermediate checks via proof. The beautiful operating diagram that you show us printed here (see figure 1), is that part of the representation to the customer?

Ramminger: Yes, also! Because we want to prove to him with this diagram that we are very well organised in the work process. But it was and is also intended for our employees, in whose awareness we want to see it firmly embedded.

It's all about central AV

DD: How is your central AV structured in itself?

Ramminger: It consists of 6 staff members, has a head and his deputy, who mainly takes care of information transfer from and to the outside and the inside.

DD: The ladies at the screens in the AV who not only calculate, but do all the order preparation and invoicing, are they reproduction professionals?

Ramminger: No, they are not. In our EDP system, all work steps are integrated in such a logical way that you can't do anything wrong if the customer advisor gives you the right information, neither when calculating the price nor when passing on the order. And in case of doubt, the AV manager is there.

IRD suggestions taken up in many ways

DD: Did you establish the scheme of your work and information process in connection with the introduction of EDP at your company?

Ramminger: No, we set up the central AV six years ago and grouped all departments around it. The impetus came from the IRD, whose method we still used to calculate manually at that time. Mr. BERNSTEIN was our contact person at that time, he later wrote the software which he now sells in his own company, together with us and the company Thomas und Kurzberg as pilot companies. In the meantime, there are already plants in Düsseldorf, Berlin, Hanau, Vreden and elsewhere.

DD: So the AV is the heart of your company, so to speak. Do you also have a technical manager?

Ramminger: We deliberately do without one, the work is directed by our AV team. Our heads of department ensure that the work is carried out correctly.

"Our sales force does not make prices."

DD: Regarding your calculation system: What do you do when one of your sales representatives outside makes a predatory price in order to get an order? Doesn't everything get a bit mixed up?

Ramminger: Our field staff do not quote prices for customers. I don't quote prices on site either, we only calculate via EDP in the company. The prices are set in consultation between the AV, the field service and, in particular cases, the management.

DD: You have a relatively large number of sales representatives. Do you pay them a fixed salary with commission or what is their remuneration?

Ramminger: They get a fixed and good salary and no commissions. We want to avoid that the people outside only "make sales". We don't need any "pick-up" types, we send technicians out there who can reliably look after our customers. Of course, we also have these people trained in sales techniques, mainly in IRD seminars. By the way, the department heads also often attend seminars at IRD. We try to give them business knowledge as well as knowledge about how to lead and guide people. We use the seminars offered by IRD very intensively.

"We have a proven track record of 90 % satisfied regular customers".

DD: What is the percentage breakdown of your clients between those who come back all the time, those who order occasionally and those who come only once?

Ramminger: Please don't take this as bragging, I would be happy to prove it: We have 90% satisfied regular customers who order regularly and come back again and again. With them and some important new customers, we achieved a 27% increase in turnover in the first half of 1988 - with a cost increase of only 3% - because we were able to attract more and more of their orders, which they would otherwise have placed elsewhere.

DD: What role does your parent company, the Main-Echo, play within this regular customer structure?

Ramminger: Naturally the biggest. But it is not yet 30 % of the turnover that comes from there. We get all the other orders on the free market, and their share is getting bigger and bigger. One third of our clients are printers, one third industrial companies and another third agencies.

DD: That's a relatively large number of agency jobs. How do you cope with the fact that agencies today have, so to speak, already focused on the possibilities of EBV, which you do not yet have?

Ramminger: We don't do any of these typical agency jobs, but only what we can handle well with our technology. These can be big jobs, such as catalogue jobs, for which you don't need EBV.

Read full article